Safe-T-Cable™ Verification Equipment

Tool Performance Verification Equipment

Repeatability and traceability in the management of Safe-T-Cable® tools at all stages of their life cycle requires periodic testing and verification. DMC supplies all the equipment necessary to perform a quick reliable verification of the application tools either on-sight, or in the metrology lab. Our objective has always been to provide a self-supporting system that does not require that tools be returned to the factory for simple testing and verification.

Repeatability and traceability in the management of Safe-T-Cable® tools at all stages of their life cycle requires periodic testing and verification. DMC supplies all the equipment necessary to perform a quick reliable verification of the application tools either on-sight, or in the metrology lab. Our objective has always been to provide a self-supporting system that does not require that tools be returned to the factory for simple testing and verification.

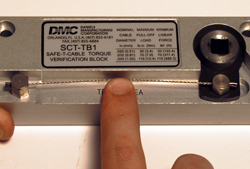

SCT-TB1 Torque Verification Block for .022″, .032″, and .040″ Safe-T-Cable®

Periodic verification of tool indenter and tensioning mechanism settings is done with the Safe-T-Cable® Torque Verification Block. Indenter setting should be verified periodically and must always be checked if the nose assembly has been removed or changed.

Periodic verification of tool indenter and tensioning mechanism settings is done with the Safe-T-Cable® Torque Verification Block. Indenter setting should be verified periodically and must always be checked if the nose assembly has been removed or changed.

Safe-T-Cable® is installed on the HEX termination points and approximately 2 lb. force is applied to the cable with your finger (or the optional SCTD013) at the line marked “TEST AREA.” If the cable does not touch the side or the bottom surface of the text area, then the cable tension is correct.

If the cable touches either the side or the bottom surface of the text area, remove the cable from the text block. Re-install another cable being careful to set the tool tension properly. If the cable still touches the side or bottom of the test area, then the tension setting of the tool is set too loosely and needs to be adjusted as explained in the tool’s instructions.

|

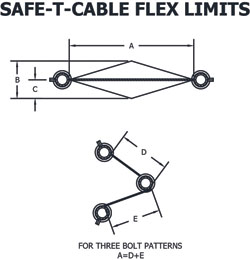

FLEX LIMITS

|

|||

A |

B |

C |

||

| 0.5 (12.7) | 0.125 (3.18) | 0.062 (1.52) | ||

| 1.0 (25.4) | 0.250 (6.35) | 0.125 (3.18) | ||

| 2.0 (50.8) | 0.375 (9.52) | 0.188 (4.76) | ||

| 3.0 (76.2) | 0.375 (9.52) | 0.188 (4.76) | ||

| 4.0 (101.6) | 0.500 (12.70) | 0.250 (6.35) | ||

| 5.0 (127.0) | 0.500 (12.70) | 0.250 (6.35) | ||

| 6.0 (152.4) | 0.625 (15.88) | 0.312 (7.94) | ||

| Place a calibrated 3/8 inch drive torque wrench (capable of indicating 30 in. lb to 110 in. lb.) into the square drive hole, orienting the Torque Verification Block on a flat surface, and apply specified force.

NOTE: Set the torque wrench according to the cable diameter being tested.

|

|

Safe-T-Cable® should remain in place during application of the measured force. If the ferrule pops off the cable, the crimp is unacceptable and the tool indenter should be adjusted. If the ferrule remains attached to the cable, recheck the cable tension as before. If the cable now touches either the side or the bottom surface of the Torque Verification Block, the crimp is unacceptable and the tool indenter should be adjusted.

Refer to Safe-T-Cable® application tool instructions, the Safe-T-Cable Training Manual, or contact DMC for more specific information on Tool Performance Verification.

|

SCT-TB1 |

Torque verification block for .022, .032, and .040 Safe-T-Cable™. |

SCT-TB1R |

Torque verification block configured for right-hand reading torque wrenches. | |

|

SCTD0001 |

Torque wrench for .022, .032, and .040 Safe-T-Cable™. |

|

SCTD013 |

2 lb. push force tester for use with Safe-T-Cable™ torque verification block. |

Advanced Technology for Safe-T-Cable™ Application Tool Testing

The SCT-TB4 Safe-T-Cable™ Electronic Verification Tester is a complete diagnostic center for Safe-T-Cable™ application tools. The SCT-TB4 is the first system approach tester for optimum Safe-T-Cable™ installation performance. It combines the simple principals of the DMC Safe-T-Cable™Torque Verification Block (SCT-TB1) and the reliable circuitry of the Alphatron “HPT” series digital electronic pull tester.

The SCT-TB4 Safe-T-Cable™ Electronic Verification Tester is a complete diagnostic center for Safe-T-Cable™ application tools. The SCT-TB4 is the first system approach tester for optimum Safe-T-Cable™ installation performance. It combines the simple principals of the DMC Safe-T-Cable™Torque Verification Block (SCT-TB1) and the reliable circuitry of the Alphatron “HPT” series digital electronic pull tester.

This one tester will provide all the information that previously required two separate testers, and increased consumption of Safe-T-Cable™ for verification of application tools. A single installed cable assembly can first be tested for minimum load – hold (flex limit test), and then be tested to destruct load (optimum tool performance). The SCT-TB4 Tester will also provide applied tension and residual tension data for engineering study and employee training purposes.

The SCT-TB4 tester is designed and packaged to survive in a shop environment, and the self contained, battery powered, design allows the user to perform tests in all areas of the shop and field support activities.

The SCT-TB4 Tester is a cost-effective quality assurance tool in most factory and maintenance applications where Safe-T-Cable™ is used.

- All DMC testers have a built-in calibration test

- SPC compatibleTraceable to NIST

- Factory calibration and support

- Rugged design, and custom carry case included

- One sample testing to the requirements of AS4536 and other standards

- Improves tool control and calibration operations

|

||

| MPT-250B-SC | Motorized pull tester for testing .022, 032 and .040 Safe-T-Cable™. | |

More Information About Safe-T-Cable™

Components: Kits, Cable Assemblies, & Ferrules