Safe-T-Cable™ Special Applications

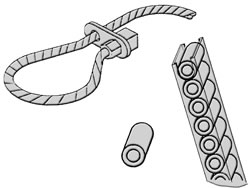

ELONGATED FERRULES

For Low Profile Faster Applications

Most Safe-T-Cable™ installations can be made with standard components and applications tools, however, there are conditions that require modification or alterations to the standard product lines to incorporate simple solutions to the difficult Safe-T-Cable™ applications, DMC has established itself as the industry leader.

Most Safe-T-Cable™ installations can be made with standard components and applications tools, however, there are conditions that require modification or alterations to the standard product lines to incorporate simple solutions to the difficult Safe-T-Cable™ applications, DMC has established itself as the industry leader.

Fasteners that have limited clearance between the safety wire hole (less than .100 inch), and the surface of the component to which the fastener is attached, can present a challenge to the installation of Safe-T-Cable™. This is due to the clearance required by the application tool nose, adjacent to the fastener.

A special elongated ferrule is available for those installations. The longer reach of the ferrule provides a stand off to the tool nose. Combine that with the radius on the end next to the fastener (radius not required on the F10-08 .020 elongated ferrules due to the small outside diameter). The angle allows the ferrule to be installed at an angle without loss of tension on the cable when the ferrule returns to the straight position.

ELONGATED FERRULES** |

|||||

CABLE

|

321 CRES |

INCONEL 625 |

INCONEL 600 |

LENGTH |

DIAMETER |

| .022*** | F10-08*** | F08-08N*** | F09-08*** | .185 max | .090 |

| .032 | F10-04 | F08-04N | F09-04 | .325 max | .105 |

| .040 | F10-07 | F08-07N | F09-07 | .325 max | .105 |

|

Consult DMC for availability of other materials. |

|||||

INCORRECT |

CORRECT |

|

|

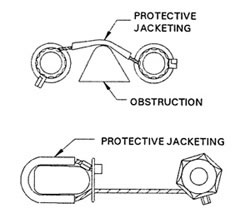

FIBERGLASS SLEEVING

FIBERGLASS SLEEVING

Safe-T-Cable™ Jacketing for Protection. It is recommended that a tubular jacket beplaced over Safe-T-Cable™ when it is installed in an area where it will be in contact with obstructions or surfaces that may damage the Safe-T-Cable™. The tubular jacket material shall be capable of meeting the temperature range of the application. It shall also be resistant to oil and chemical environments.

- 50 Foot Spool

Part Number: SCTD010

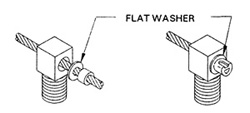

FILLER WASHER for .022, .032 and .040 Safe-T-Cable™

Applications where Safe-T-Cable™ is to be installed through a hole having a diameter greater than.095 inch (2.4 mm), but less than .200 inch (5.08 mm) can be accommodated by a filler washer. NOTE: Compatible materials are required and care must be taken to restrain the washer during removal/service operations.

Applications where Safe-T-Cable™ is to be installed through a hole having a diameter greater than.095 inch (2.4 mm), but less than .200 inch (5.08 mm) can be accommodated by a filler washer. NOTE: Compatible materials are required and care must be taken to restrain the washer during removal/service operations.

- Filler Washer, Material: 321 CRES

Part Number: FW10-1 - Filler Washer, Material: INCONEL 600

Part Number: FW09-1

SELF-LOOPING Safe-T-Cable™

It is DMC’s mission to be responsive to the needs of Safe-T-Cable™ users. One more example of the DMC responsiveness is the Self-Looping Safe-T-Cable™. There are many applications for lockwire where holes do not exist in a fastener or other part of the assembly. The common practice is to wrap the wire around a casting web, pin, or similar feature, and then anchor the other end to the fastener. The Self Looping Safe-T-Cable™ provides the user a means of anchoring a threaded fastener to almost any structure.

It is DMC’s mission to be responsive to the needs of Safe-T-Cable™ users. One more example of the DMC responsiveness is the Self-Looping Safe-T-Cable™. There are many applications for lockwire where holes do not exist in a fastener or other part of the assembly. The common practice is to wrap the wire around a casting web, pin, or similar feature, and then anchor the other end to the fastener. The Self Looping Safe-T-Cable™ provides the user a means of anchoring a threaded fastener to almost any structure.

The operator simply wraps the cable through (or around) the structure, and back through the hole in the captive link at the head of the cable. The operator then pulls the slack out of the cable, and threads it through the head of the fastener, and terminates to with a standard application tool.

Another type of application where the Self-Looping Safe-T-Cable™ offers a clear advantage over lockwire is when it replaces lockwire on turnbuckles, castellated fittings, and other applications where holes are not provided at either end of the cable. In those cases, the cable is threaded around the fittings and terminated back at the hole in the captive link on the head of the Safe-T-Cable™.

Safe-T-Cable™ SELF LOOPING KIT

|

||||

MATERIAL/PART NUMBER* |

DIAMETER

|

LENGTH**

|

||

321 CRES* |

INCONEL 625 |

INCONEL 600 |

||

| C10-312JA | C08-312NJA | C09-312JA | .040 | 12″ |

| C10-318JA | C08-318NJA | C09-318JA | .040 | 18″ |

| C10-324JA | C08-324NJA | C09-324JA | .040 | 24″ |

| C10-212JA | C08-212NJA | C09-212JA | .032 | 12″ |

| C10-218JA | C08-218NJA | C09-218JA | .032 | 18″ |

| C10-224JA | C08-224NJA | C09-224JA | .032 | 24″ |

| C10-112JA | C08-112NJA | C09-112JA | .022 | 12″ |

| C10-118JA | C08-118NJA | C09-118JA | .022 | 18″ |

| C10-124JA | C08-124NJA | C09-124JA | .022 | 24″ |

| *Kit part number applies to one cable assembly and on ferrule. Add “PKG” to Part Number (shown in chart) when ordering a 50 piece cartridge of Safe-T-Cable™ ** Other length combinations are available |

||||

NOTE: Individual cable assemblies and special ferrule combinations areavailable. Consult factory for availability/details

BRANDED Safe-T-Cable™

Logo/Distinctive Mark Identification by the Factory

Onemore value added service from DMC tothe users of Safe-T-Cable™ is the application of a permanent mark (unique to one customer only)on the head of the Safe-T-Cable™. The distinctive brand on the cable end fitting, when installed onan engine, accessory, or other assembly, becomes a reliable identification flag that can be used to trace the final assembly to a date, location, or other significant purpose. The most common reasons that the DMC Safe-T-Cable™ branding service has become very popular are the following:

Onemore value added service from DMC tothe users of Safe-T-Cable™ is the application of a permanent mark (unique to one customer only)on the head of the Safe-T-Cable™. The distinctive brand on the cable end fitting, when installed onan engine, accessory, or other assembly, becomes a reliable identification flag that can be used to trace the final assembly to a date, location, or other significant purpose. The most common reasons that the DMC Safe-T-Cable™ branding service has become very popular are the following:

WARRANTY TRACEABILITY – Safe-T-Cable™ with a corporate logo or other distinctive mark can be applied by the factory or authorized repair station to limit warranty claims. Products returned for warranty repair can be easily inspected to verify that the factory applied logo or symbol is on the head of each Safe-T-Cable™.

SERVICE LOCATION VERIFICATION – The exact location of the last service/repair of a product or component can be easily identified of your organization utilizes a well thought-out Safe-T-Cable™ branding program. The application of distinctive mark, logo or initials allows easy verification and/or routing of product for repair, rework, or function.